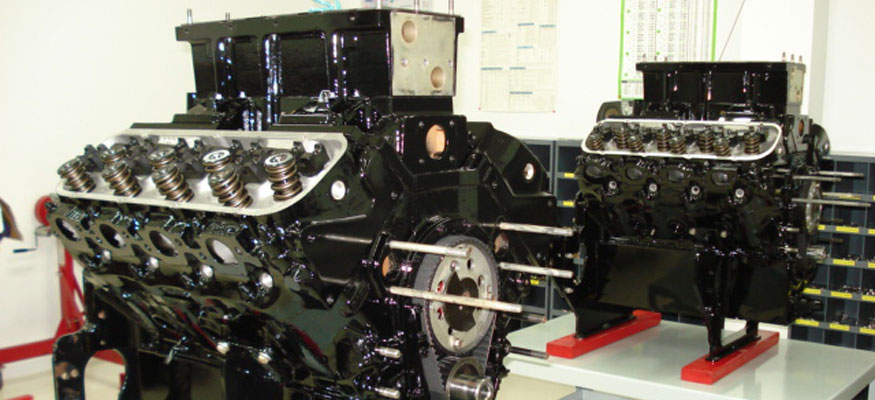

Potter On Performance: Rebuild Your Engine Or Buy New?

The question has been asked of us of at Potter Performance Engines many times: “Should I rebuild my boat’s current engines or just buy new engines?”

The answer? Every situation is different and can only be answered objectively after first disassembling and inspecting the engine in question.

I can’t tell you how many times a customer calls asking for a price on a new engine. My first question is always, “What’s wrong with your existing engine?” Many people think that because an engine is damaged, it’s not worth rebuilding. This is not necessarily the case. In fact the majority of engines coming through our shop over many years were not nearly as bad as the customer had expected.

Let’s say you have an average big-block marine engine making approximately 600 hp. And let’s say that engine sells new for around $36,000. Now, the damaged engine in question has broken a connecting rod and a damaged block and oil pan. Let’s say the average rebuild cost is about $10,000 and the block, rods and oil pan cost roughly $4,500 plus an additional $1,500 for related machining. Now you’re looking at approximately $16,000 for the rebuild—big difference between $36,000 and $16,000, right?

That’s just an example. It’s important to understand that not all engines or internal parts are the same and the costs of these items vary greatly. In most cases, we’ve found that engines that were more expensive when they were new are far less expensive to rebuild than replace.

A lot of customers ask us why it costs so much less to rebuild their engine instead of replace it. The reason for this is mainly due to the cost of all the external engine components. Ignition systems, fuel systems, brackets, mounts, couplers and so on really add up. They can sometimes cost more than an entire long block engine.

That’s not to say it is always less expensive to rebuild. In some cases when it comes to small displacement engines, it can be a better value to go with a factory-remanufactured engine. Case in point: We had a customer a few years ago who had his 350 MPI inboard engines fill with saltwater. Once we disassembled the engines, we found severe corrosion to almost all internal components including the block.

Ron Potter: “Good parts aren’t cheap—and cheap parts aren’t good.”

After working up a detailed estimate and checking the cost of a factory-remanufactured engine, it was a no brainer. We were able to get our customer a complete engine with a one-year warranty for less money that it would be to rebuild.

We like to address every situation as if we were spending our own money. Is it better to rebuild this engine or are we doing our customer a better service by replacing it?

Here’s the bottom line: Find a respected engine builder. Let him inspect the engine and give you the options. Ask for a detailed list of parts being replaced and photos of the damaged items. Keep in mind that reputation is everything. Do a little research and talk to other people who have had their engines rebuilt.

And never shop engine work by cost. Good parts aren’t cheap—and cheap parts aren’t good.

Editor’s Note: Engine builder Ron Pottter’s next column will appear on Monday, Feb. 1.

Related Stories

New On Speedonthewater.com: Bi-Weekly ‘Potter On Performance’ Column

Catching Up With Ron Potter